Address

Shristi Enterprises, B-6, Garchaz Complex, Raipur, Chhattisgarh, India

Vinyl polysiloxane impression material

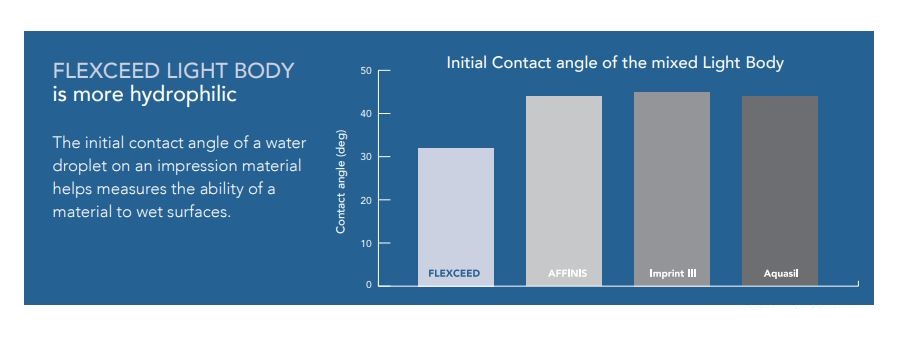

FLEXCEED, with its lowest contact angle, displaces moisture and lows into subgingival areas rather than lowing away to mucosal surfaces, thus producing accurate impression detail.

It has High Initial Hydrophilicity & Viscosity . It gets pushed into the sub-gingival area easily to register the details. The flow of FLEXCEED Putty-Wash is better than most of the brands.

FLEXCEED LIGHT BODY is more hydrophilic:

The initial contact angle of a water droplet on an impression material helps measures the ability of a material to wet surfaces

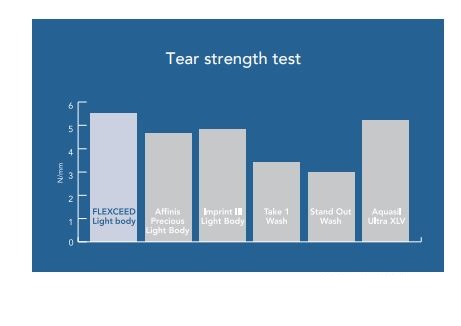

FLEXCEED exhibits the highest tear strength to give an accurate impression detail everytime.

The subgingival and interproximal regions of the impression are often very thin and can tear during the removal of the impression. FLEXCEED has been tested to have the highest strength to resist tearing in comparison to other vps impression materials.

The subgingival and interproximal regions of the impression are often very thin and can tear during the removal of the impression. FLEXCEED has been tested to have the highest strength to resist tearing in comparison to other vps impression materials.

The subgingival and interproximal regions of the impression are often very thin and can tear during the removal of the impression. FLEXCEED has been tested to have the highest strength to resist tearing in comparison to other vps impression materials.

INDICATIONS:

I. Single step putty wash impression

STEP 1:

Take equal quantities of FLEXCEED base & catalyst using the prescribed scoop

STEP 2:

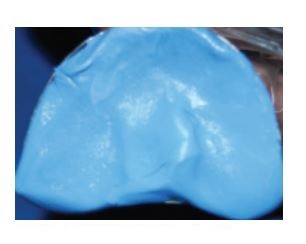

Knead the FLEXCEED base & catalyst until a uniform blue color is achieved

STEP 3:

Load the FLEXCEED putty mix on the tray

STEP 4:

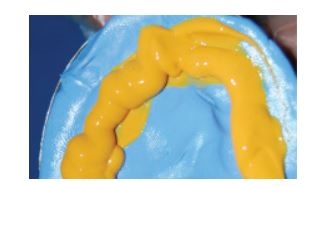

Inject the FLEXCEED light body onto the putty mix making sure that the nozzle remains immersed to prevent air entrapment

STEP 5:

Using the intra-oral tips, inject the FLEXCEED light body directly around the prepared tooth

STEP 7:

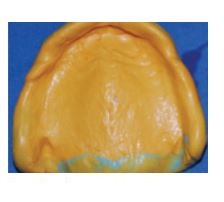

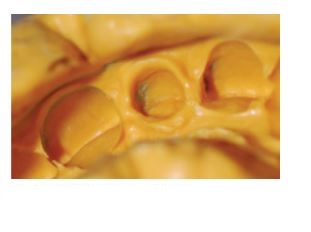

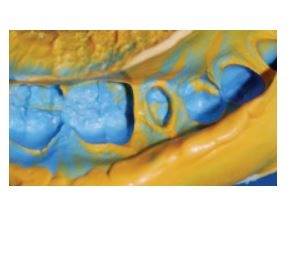

Final impression is easy to read due to the contrasting colour of FLEXCEED

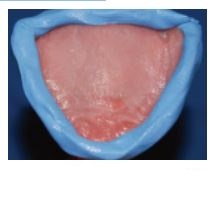

II. Impression for complete denture

STEP 1:

Apply GC tray adhesive

STEP 2:

Bourder moulding using FLEXCEED putty

STEP 3:

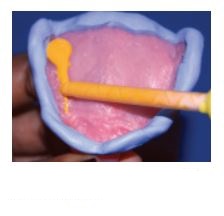

FLEXCEED light body is loaded onto the individual tray

STEP 4:

Completed upper impression

Double step putty wash impression

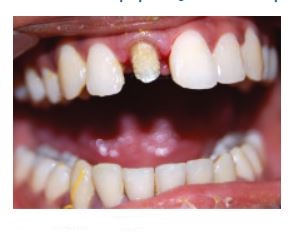

STEP 1: Prepared tooth for crown

STEP 2: After applying GC tray adhesive, FLEXCEED putty Putty impression is taken is loaded on the stock tray

STEP 3: Putty impression is taken

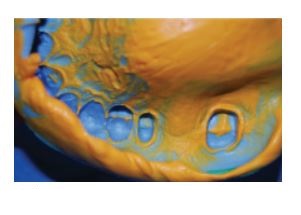

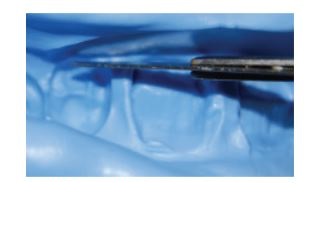

STEP 4: Using the putty cutter, create a space for the light body

STEP 5: Inject the FLEXCEED light body around the prepared tooth, then immediately re-seat the putty tray impression

STEP 6: Final impression using FLEXCEED

Dual Arch impression

STEP 1:

FLEXCEED putty is loaded onto a dual arch tray

STEP 2:

FLEXCEED Light Body is injected over the putty Final impression. then impression is taken

PHYSICAL PROPERTIES:

| LIGHT BODY | PUTTY | |

| Mixing Time | 20 sec | |

| Total Working Time | 2 min | 1 min |

| Minimum time in Mouth | 3 min | 3 min |

| Elastic recovery | More than equals 98% | More than equals 98% |

| Strain in Compression | 2.5-3.5 % | 1-2% |

| Linear dimensional change | Less than or equals to 0.20% | Less than or equals to 0.20% |

| Detail Reproduction | 20 μm | 75 μm |

| Compatibility with Gypsum | 20 μm | 75 μm |

GC Flexceed Putty + Light Body Kit:

"Providing quality product with right information of latest technology to cater requirement of medical professionals."

Shristi Enterprises has been providing excellent services for last many years. The support services provided are very good and they are very prompt in dealing with any of the issues pertaining to instruments.

Shristi Enterprises is dedicated for health care services always ready to provide prompt services to the customer whenever needed . Executives and dealer are ready to help any time .

Amit Sharma

Founder

Hi, I am Amit Sharma, founder of Shristigroup. I started this organization in 2001. Since inception my vision is to make Shristi Enterprises the number one organization in medical & healthcare supplies in Chattishgarh, INDIA, After achieving the same, now I am looking to expand its operation across India.

We have a team of 50+ workforce which include people who have worked at top positions in Sales & Customer Service of reputed medical instrument manufacturer companies. We have the state of the art Infrastructure which includes 10,000 sqft warehouse in Raipur (our HQ) & satellite offices in Bhopal & Indore (M.P.) & in Mumbai. Apart from warehousing, we have our own transportation system to ensure timely & safe deliveries to all our customers.

For product sustainability, material storage and logistics is number one priority for us. We have our in-house supply chain management integrated with freight forwarding and contract logistics to provide seamless distribution process from manufacturers to our customers.

We also use latest softwares to ensure we operate at maximum efficiency. We have state of the art, third party developed accounting, employee management, inventory management & delivery tracking software.

Our satisfied customers include AIIMS Raipur, Bhilai Steel Plant, Government Medical College Raipur and various private hospitals in MP, CG and rest of INDIA.